Fire Gas Detector

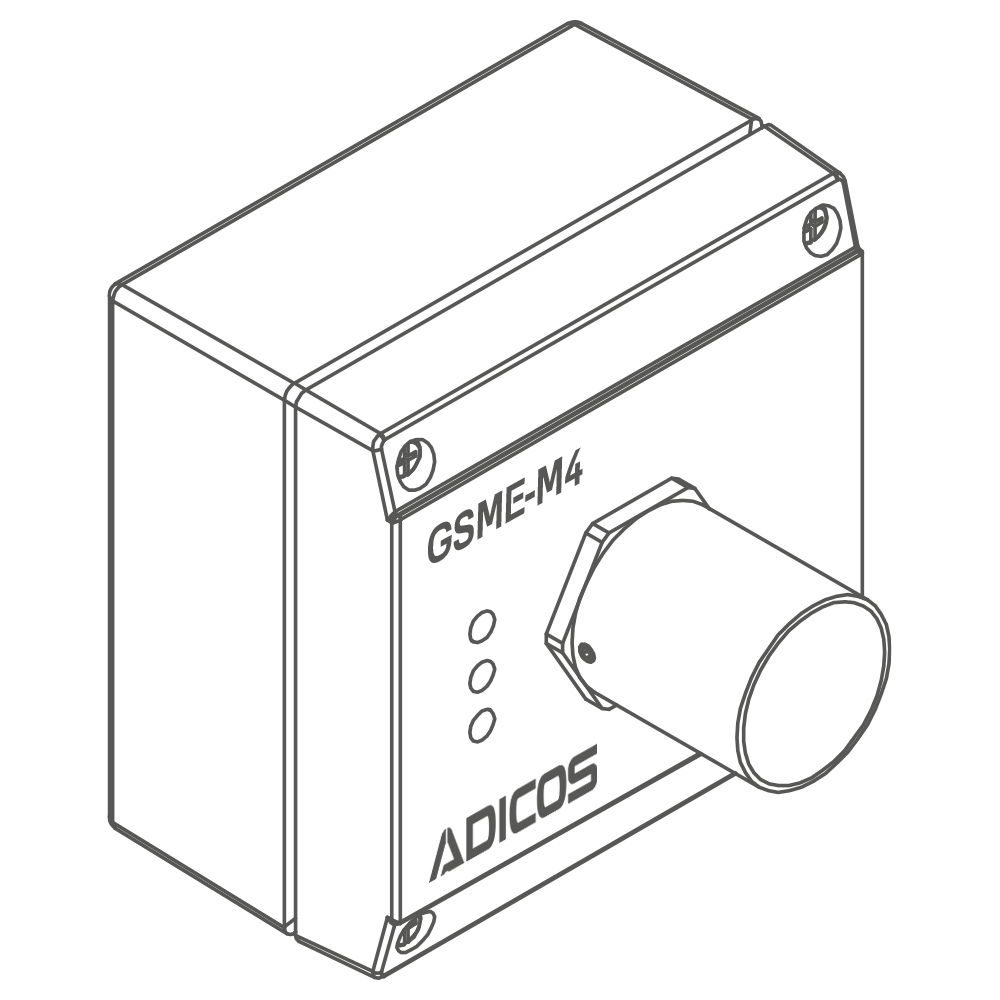

GSME-M4

The GSME-M4 fire gas detector recognizes open and concealed smoldering fires early in the incipient stage. Four parameterizable semiconductor gas sensors are used for this purpose. They are highly sensitive and yet robust. Thanks to sintered metal filter technology, the GSME-M4 detector is protected against the ingress of dust and dirt.

We are pleased to assist you.

Are you interested in our ADICOS system or are you planning a specific project? We will be pleased to assist you. Please contact us by phone at +49 2162 3703-0 or by e-mail (adicos@gte.de) or send us a non-binding project inquiry via our inquiry form.GSME Fire Gas Detectors

ADICOS GSME ("Gas Sensor Detection Units") are compact fire gas detectors for early detection of all types of concealed and open fires - and that already in the incipient stage. Highly sensitive yet robust and extremely safe against spurious alarms, they are ideal for fire gas detection in industrial environments. Four parameterizable semiconductor gas sensors monitor and evaluate the concentration curve of fire-characteristic gases according to multi-criteria technology. This enables the GSME detectors to distinguish real fires from interference signals. With the ADICOS software, all detector states and concentration curves can be displayed graphically. Sensitivities as well as alarm thresholds can be parameterized individually for each detector. The GSME fire gas detectors can be used in almost any indoor plant area, taking into account the air flow conditions.

Industrial Fire Detection ADICOS

adicos@gte.de

Technical Data GSME-M4

| Gas sensors: | CO | H₂ | HC | NOx |

| Dimensions: | 120 mm x 100 mm x 100 mm (L x W x D) |

| Weight: | 0.64 kg |

| Protection class: | IP64 |

| Explosion protection: | no |